Improving cooling water pump system for rolling rack

1. Project information

- Status: The water pump station maintains a fixed water pressure on the pipeline to cool the hot rolled steel racks. Pump motor starts star - delta, always running at full capacity.

The system pressurizes by a pressure regulator valve, when the water pressure is greater than the preset pressure, the pressure valve will automatically discharge the excess water pressure to the storage tank.

- Project requirements: How to save electrical energy and maintain stable water pressure on the pipeline?

2. Solution of Bao An Automation

- Solution: Upgrade the system of monitoring and control cabinets at the pump station and the central control room by using a closed-loop control system to stabilize the water pressure on the pipeline through the pressure sensor and pressure controller – Autonics with LS inverter to control pump motor.

- Advantages of the solution:

+ The water pressure on the pipe is automatically adjusted and always stable.

+ The pressure is set easily from the controller, the pump station is still simple to operate, without causing pressure deviation.

+ Save electrical energy, reduce CO2 emissions: The inverter controls the pump motor to rotate quickly and slowly to maintain water pressure on the pipeline, no longer releasing excess pressure on the pipeline through the pressure regulator valve. .

+ Increase pump motor life, because the pump motor current flowing through the inverter is 4 - 8 times smaller than running directly from the grid.

+ Payback period of less than 1 year with the amount of energy saved.

3. Scope of application

- Manufacturing plants need to improve the cooling pump system because it is not suitable (mechanical pressure relief valve, ...) which consumes power, wastes water and reduces equipment life.

- Heavy industrial production industries that need to use pump systems for cooling: metallurgy, steel billet production, etc.

4. Actual picture

Image of Improved cooling water pump – Bao An Automation

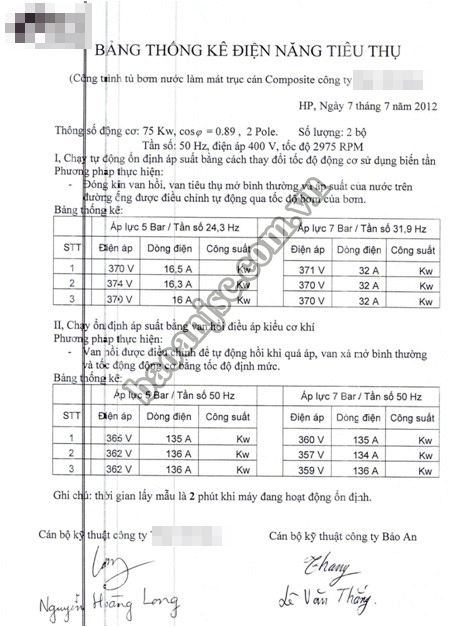

Image: Power consumption statistics table comparing 2 methods before and after improvement

Contact for detailed advice:

Bao An Technical Service Joint Stock Company - Bao An Automation

Address: Van Tra, An Dong, An Duong, Hai Phong City

Hotline: 0936.985.256 VND

Website: https://baoanjsc.com.vn

Email: baoan@baoanjsc.com.vn

Fanpage: https://www.facebook.com/BaoAnAutomation