Brushless DC motor: structure, working principle and application

1. Brushless motor concept

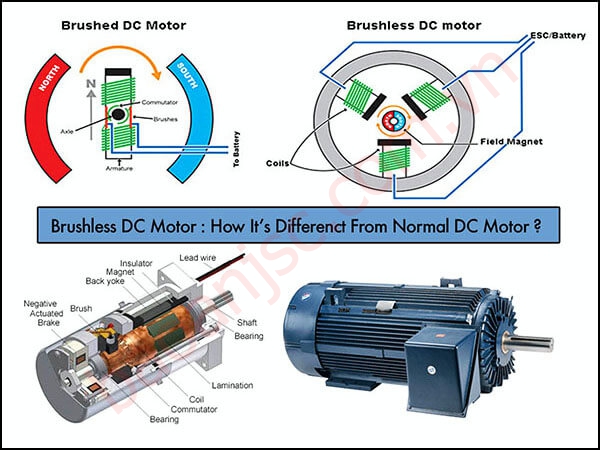

A brushless motor (BLDC) is an electric motor that relies on a permanent magnetic field and a sensor to determine its position, completely without using brushes (brushes) to help eliminate friction. From there, it helps to reduce the noise for the engine to operate smoothly, and at the same time save energy use.

The motor is completely brushless to help eliminate friction

Similar to common synchronous motors, the windings of the BLDC are also placed at an angle of 120 degrees from each other in the stator space. The magnets are also firmly attached to the rotor body, capable of exciting the motor. In particular, the operation of the mini brushless motor requires a rotor position sensor to help the motor operate better.

2. Brushless motor construction

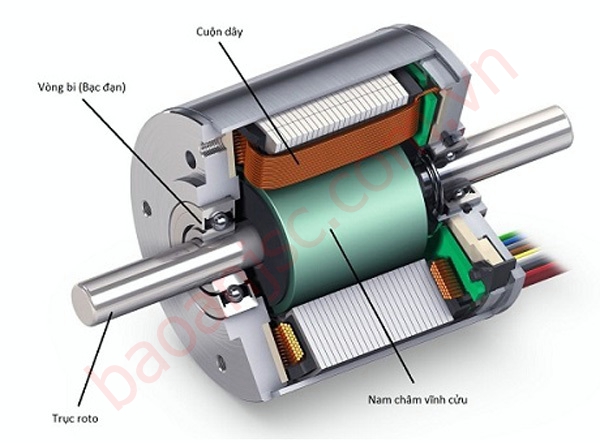

Brushless motor consists of the following parts:

- Stator: Usually consists of iron cores (electrical engineering steel sheets are insulated together) and windings. The winding of a brushless motor is also different from that of a conventional 3-phase AC motor.

- Rotor: Basically, this part is similar to other permanent magnet motors.

- Hall sensor: Due to the characteristic of the BLDC motor's anti-electromotive force, it has a trapezoidal shape, so its normal control configuration also requires a sensor to determine the position of the rotor magnetic field in relation to the winding phases stator. To do that, people often use Hall effect sensors, which can be called Hall sensors for short.

Structure of brushless motor

3. Working principle of brushless motor

As the name implies, brushless DC motors are characterized by the use of no brushes. With brush motors, the brush will pass current through the commutator to flow into the windings on the rotor.

Brushless motors do not transmit current to the rotor windings because the windings are not on the rotor at all. Instead, the main rotor is a permanent magnet, it has coils that do not rotate but are fixed in place above the stator. Since these coils do not move, neither a brush nor a commutator is needed.

In a brushless motor, the permanent magnet is rotated by changing the direction of the magnetic field generated by the coils arranged stationary around it. To control that rotation, you need to adjust the magnitude of the combined direction of the current flowing into these windings.

4. Brushless motor advantages

A typical brushless motor has 3 windings on the stator, so it will have up to 6 electrical conductors extending from the windings themselves. Meanwhile, 3 of these wires will be connected internally, with the remaining 3 to extend from the motor body. Wiring in the housing of a BLDC motor is more complicated than when you only connect the negative and positive terminals of the power cell.

Do that, the powerpoint of the engine are not known to as:

A big benefit of this dynamic basis is the performance result, as we can be driven continuously at maximum rotational force (also called torque). In contrast, the base of the time will receive the maximum torque only at certain points inside the rotation. This is also the home, which is why even motors that are no more than mini can provide significant power.

The second motive for not prioritizing is its good test performance. The BLDC motor is controllable, using a feedback mechanism to precisely deliver the torque and rotational speed desired by the user. The main control is to get the boost and the life less, if it's auto battery powered it will help to extend the battery life and lifespan.

The BLDC motor is also considered a motor with high durability and low electrical noise because it has no brushes. With a brush motor, the brush and commutator will be worn out due to constant, frequent motion contact and also generate sparks and heat at the point of contact.

In particular, electrical noise is considered the result of strong sparks that will often appear in the areas where the brush passes through the openings inside the commutator. This also explains why BLDC motors are generally considered to be more suitable for applications where electrical noise is to be avoided.

BLDC motors are also considered to have high durability

5. Ideal application for brushless motors

Brushless motors have long been used in the construction of washing machines, air conditioners, and other home electronics. And recently, this motor has also appeared in fans, because of their high efficiency, which has significantly reduced the amount of power consumed by the fan.

BLDC is also being used to operate the vacuum cleaner. In some cases, a change in their control program setting will result in a major breakthrough in rotational speed. This is an example of the first-order controllability of these motors.

Brushless motors are also being used to spin hard drives. Because of their durability, the drive will last longer for a long time. At the same time, the energy efficiency of the engine also contributes to reducing energy consumption.

The BLDC engine is also ideal for drone applications. Their precise position control makes them particularly suitable for multi-cruise drones, which are controlled by precisely controlling the position and rotational speed of each propeller.

Conclude

In the article above, we learned that brushless motors offer excellent performance, controllability, and longevity. Careful, thorough control is essential for you to get the most out of these engines.

Contact for detailed advice: 093.659.2556

- Bao An Technical Service Joint Stock Company - Bao An Automation

- Address: Van Tra, An Dong, An Duong, Hai Phong City

- Hotline: 093.659.2556

- Website: https://baoanjsc.com.vn

- Email: baoan@baoanjsc.com.vn

- Fanpage: https://www.facebook.com/BaoAnAutomation