EASY LOGISTICS AUTOMATION WINS YOU CAN MAKE NOW WITH COGNEX

Automation is rapidly transforming the logistics industry.

It has been pushed by large enterprises, particularly Amazon, but also large national retailers with enormously high throughputs, aggressive delivery schedules, and massive investments in facilities and technology.

But that doesn’t mean that these technological advances only make financial sense for massive throughputs, multiple facilities, and seven-figure capital investments. There are specific technology and process changes that operations of any size can make that can significantly improve throughput and have excellent ROI. There are quick investments in automation you can do now that ensure scalability so that the business does not hit bottlenecks as volumes increase.

The three easiest and most cost-effective means of automating logistics involve changes to how barcodes are read.

Moving from handheld scanning to presentation reading

Handheld scanners are what made the widespread use of barcodes to identify and track cartons and items possible. They are inexpensive, easy to use, and flexible for a wide range of uses. They use human minds and bodies to be pointed at the code, and so can be used for shelf reading, etc.

But they are a good example of a scaling problem. The process of handheld scanning is highly manual and relatively slow.

Using a handheld barcode scanner to read a barcode on a package takes three actions: pick up the product in one hand, hold the handheld scanner in the other, then scan the code by holding the scanner up to the code and triggering it. It works at the pace of an individual operator.

Scanning can be streamlined significantly by converting to presentation reading, which is always on and in a fixed location. The operator can quickly process items or packages by using one or two hands to pass an item under the barcode reader. This type of scanning is perfect for a variety of logistics applications such as unloading a truck, pick and pack operations, as well as building and breaking down pallets.

Presentation reading

By eliminating a range of repetitive movements, particularly involving pivoting, and picking up objects of various weights one-handed, presentation readers reduce worker fatigue and prevent injuries, which will rise as volumes increase in the absence of increased automation. Converting from a handheld scanner to presentation reading can increase productivity by 20% and lower the cost per item picked by 17% with an ROI period of only a few months.

Moving from laser technology to image-based barcode reading

A laser scanner has three essential parts: a light source, a sensor that detects the variations in the light reflected from the barcode, and a decoder that converts those variations into data which is then recorded, tracked, and put into databases.

While they are inexpensive and familiar, laser scanners have a key shortcoming: their read rate. They have trouble reading damaged, creased, smudged, or poorly printed barcode labels.

Image-based scanners have significantly higher read rates and come with a host of other advantages. They can read codes from a variety of angles, they can read the increasingly common 2D codes, and they can read multiple barcodes simultaneously. They can also read barcodes on smartphone screens and other displays.

In addition to reading barcodes unreadable by laser scanners, image-based barcode readers support process improvement in a way that laser scanners can’t. In an image-based reader, each capture of a barcode is an image. In cases of no-reads, the images can be used for root-cause analysis and real-time monitoring. This can reveal that the source of the problem is a printer, a labeler, or that boxes are being placed in the wrong orientation on the conveyor, thus allowing for quick modifications to get rates back up. This image-based data also helps maintain vendor compliance on incoming freight.

Smart camera data

Image-based barcode readers can also be augmented with High Dynamic Range Plus (HDR+) algorithms that increase contrast, liquid lenses for quick autofocusing on variously sized containers, and various lighting kits that increase brightness while minimizing glare.

Used in an overhead, fixed position, image-based barcode readers can dramatically increase throughput by minimizing unreadable or misread barcodes at high line speeds, while also providing the data needed to optimize operations.

Moving from a single overhead scanner to a multi-sided tunnel

If a distribution center receives goods from a variety of different vendors it can be difficult to manage barcode quality, size, and location, as well as package size and configuration. Workers must move the packages so that they are oriented correctly for reading. All this manual work costs time and money and is an inefficient way to scale operations as volumes ramp up.

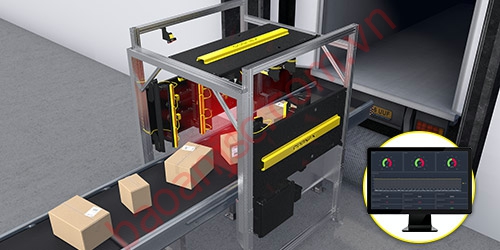

The solution for this is to have multiple simultaneous readers at different orientations so that they can simultaneously read more than one side of each package. The most common setups are 5-sided (all sides except the bottom) and 6-sided (including the bottom) scanning. The resulting configuration surrounds the conveyor and is called a barcode reading tunnel.

Outbound scanning tunnel

Tunnels do require significantly more investment than a single overhead reader, but when a business requires even higher rates and fewer no-reads, a multi-sided tunnel is a next step that can

SOURCE: COGNEX

For more information:

- Address: Vân Tra, An Đồng, An Dương, Hải Phòng city

- Hotline: 0936.985.256

- Website: https://baoanjsc.com.vn

- Email: baoan@baoanjsc.com.vn.

- Fanpage: https://www.facebook.com/BaoAnAutomation

- Bao An Automation - Distributor of SICK electrical equipment in Vietnam

- Economy digital torque meter

- Dong IL ASG-A050W antistatic bar: Effective solution for industrial environment

- Bengine EBS Medium Torque Series Electric Screwdriver

- CSS High Resolution Sensor - SICK's ultra-precise color detection solution