Maintenance and cleaning of antistatic device

1. REASONS NEED TO MAINTENANCE AND CLEANING OF ELECTRICAL DETERMINATION EQUIPMENT?

Static eliminator has the effect of neutralizing an electrostatically imbalanced object by generating a multitude of positive and negative ions that help the unbalanced object receive the ions it lacks to return to equilibrium.

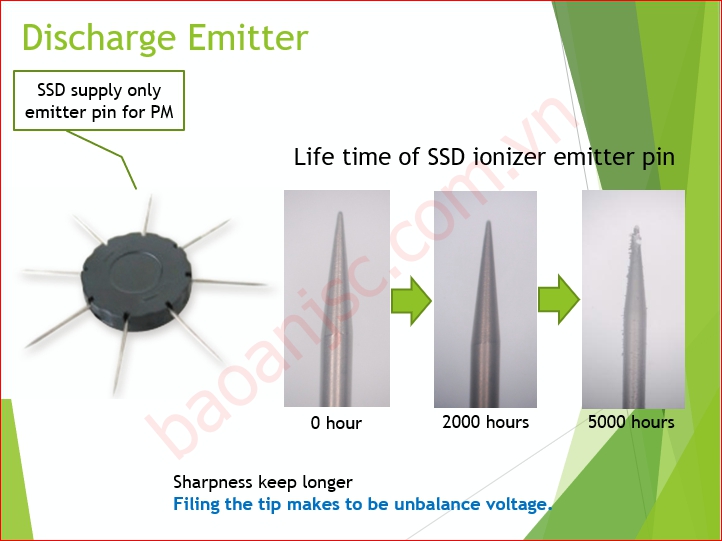

Anti- static devices such as fans , bars , guns ... use the principle of high voltage (4kV-7kV) on the needle tips to generate ions

However, the problem is that after a period of use, the tip of the needle will be dusty

SiO2 will form on the tip of the needle as a side effect of the high voltage.

Harm: Reducing the amount of ions generated from the tip of the needle leads to a decrease in the effectiveness of antistatic, even if the device is not cleaned regularly

The tip of the needle is dusty after a period of use

2. INSTRUCTIONS FOR CLEANING OF ELECTRICAL DEVICE BAR

With compressed air eliminators such as antistatic rods, it is advisable to control both the quality of the compressed air, oil and steam flows because the amount of dirt in these three factors can also affect the durability of the tip. needles and products.

Regularly clean both the inside and outside of the anti-static bar

Clean the antistatic needle with IPA-absorbent cleaning cloth for the best cleaning effect.

Operate the device in a safe environment, without moisture or in an environment with electrical leakage.

The less dust in the working environment, the longer the life of the equipment.

Bar needle tip after use time

3. INSTRUCTIONS FOR CLEANING OF ELECTRICAL FANS

To increase the life and working capacity of the fan, regular maintenance is indispensable. You can refer to the following steps:

– Turn off the power switch.

– Unplug the power adapter at the fan.

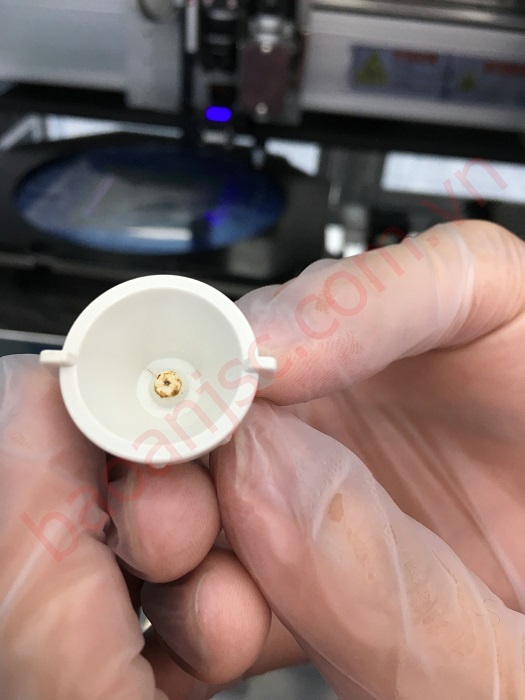

– Remove the needle unit from the front of the fan (turn counterclockwise).

– Use a soft cloth, brush, cotton swab to clean the fan and needle (if the needle is worn, it should be replaced). Note, clean the antistatic needle with IPA-absorbent cloth for the best cleaning effect.

– Install the fan in reverse of the removal.

Clean the needle part of the fan after a period of use

4. CLEANING TIME OF ELECTRICAL DEVICES

Depending on the anti-static technology, usage level, dust level of the environment, factory regulations, the frequency of cleaning equipment will be different. The important thing is to what extent will the antistatic effect decrease?

As recommended by the manufacturer, the antistatic equipment should be cleaned once a week. However, with Dong-IL brand antistatic products , it is still possible to maintain good antistatic effect after 4-6 months of use without cleaning.

5. DONG-IL BRAND ELECTRICAL DEVELOPMENT EQUIPMENT

Dong-IL is a Korean brand that provides the most popular anti-static equipment today. Dong-IL's antistatic products are highly appreciated by:

Outstanding product quality, rigorously tested according to welding standards.

All anti-static products of Dong-IL meet RoHS2 standard - the standard to limit hazardous substances in electrical and electronic equipment (regulated by European law).

The fan, gun, rod, nozzle ... and electrostatic testing equipment are suitable for use in places where static electricity is required in the manufacturing plant.

In Vietnam, Bao An Company is currently an authorized distributor of Dong-IL electrostatic suppression equipment .

Customers who want to buy or need advice on Dong-IL anti-static solutions , please contact Bao An with the information below for thoughtful support.

Bao An authorized distributor of antistatic equipment Dong-IL (Korea)

Bao An distributes Dong-IL devices in Vietnam market:

- Competitive price.

- Item is available with common item code.

- Fast delivery with order code.

- Open, delivery 24/7 for emergencies.

- Consulting and technical support.

Contact for detailed advice:

BAO AN AUTOMATION - BAO AN TECHNICAL SERVICE JOINT STOCK COMPANY

- Address: Van Tra B project area - An Dong - An Duong - Hai Phong

- Hotline: 0936.985.256 VND

- Email: baoan@baoanjsc.com.vn

- Website: https://baoanjsc.com.vn

- Fanpage: https://www.facebook.com/BaoAnAutomation

Articles you should see:

- ION BLOWER SF-40A

- Ion Blower DONG IL AMF-AE Series

- Ion Blower DONG IL MF-90 Series . Ion Blower DONG IL MF-90 Series

- Ion Blower DONG IL AMF-95 Series

- Anti-static gun - ION GUN DONG IL ZM-G1G Series