What is the carbon brush?

1. What is a carbon brush ?

The carbon brush is a conductive material that transmits and connects electricity from the stationary part (Stator) to the rotating parts (Roto). Brushes are used in AC electric motors or DC electric motors , which are commonly used in the manufacturing industry using wound motors. Depending on the actual load and current, the material used to make the charcoal may change. In addition to the main component, carbon can also use some other ingredients such as copper or nickel ...

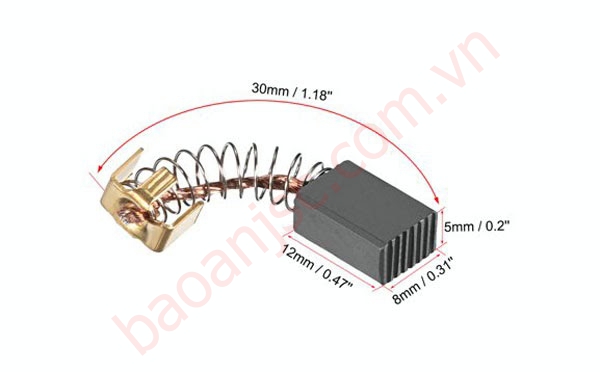

Carbon brush image

2. What are carbon brushes used for?

Carbon brush is a detail that is widely used in industrial machines, household electrical appliances and in daily life. Some applications of carbon brushes can be mentioned as:

- Use with motor of car or motorcycle.

- In some types of household machines such as vacuum cleaners, dryers, blenders.

- Used in decorations, toys, door locks, small motors.

- Carbon brushes are also used in generator engines, industrial motors ( screw guns , air compressors , air blowers...)

3. Structure of carbon brush

The shape of the brush looks like a small brush made of carbon. One end of the brush is a carbon plate attached to a copper wire, the other end is a "pin" that can be attached to a frame or bracket. The brush is in constant contact and supplies power to the commutator by means of a spring called tweezers. There are several types of springs commonly used in carbon brushes, such as: trigger springs, leaf springs, coil springs.

Carbon brushes are usually made up of 4 parts: the terminal, the wire, the spring and the carbon plate.

A manufacturer-designed brush lead is located inside the charcoal piece about 3.0 - 5.0mm, this contact part will be glued or used a latch. On the outside of the charcoal plate is often marked so that the user can identify how far the wire is plugged into the charcoal piece, this helps the user to know how much wear of the brush is left, about to need to be replaced. brush or not.

4. Working principle of carbon brush

The carbon end of the brush will be pushed by the spring so that it is in continuous contact and slides on the commutator, which helps maintain the current for the rotor part.

The spring will help the brush to make continuous contact and slide on the commutator

In order for the brush to move easily when the spring pushes it into contact with the commutator, the distance from the brush edge to the surface next to the holder is designed by the manufacturer so that the gap is only about 0.8 -1mm wide. If this distance is not standard (wider or narrower than the distance 0.8 - 1.0mm), it will lead to the brush's damage or unstable operation.

- The distance between the brush and the holder is greater than 1.0mm: it may cause the brush to shake, making contact unstable, long-term operation can cause uneven brush wear, easy to generate sparks .

- If the distance between the brush and the holder is less than 0.8mm: it will cause the brush to expand during use due to high temperature, which can cause the brush to get stuck and damage the holder and brush.

5. Some popular types of carbon brushes

Based on the structure, we can classify brushes into several types as follows:

- Paired brush: Simply put, this is a brush created from combining two single carbon brushes into one through a cable or pole.

- Sandwich brush (Sandwich brush): This is a type of brush that has many pieces of carbon (carbon) stuck together into a block. The pieces of coal that are put together can be the same or different in terms of materials.

- Split brush: This is a type of brush in which the pieces are not rigidly bonded together. When operating, the coal pieces can move relative to each other. Like sandwich brushes, split brushes can be made up of pieces of charcoal of the same or different materials.

- Single brush (Insert brush): This is a type of brush with a piece of charcoal that is commonly used.

6. How to choose the right type of brush?

In the process of using and operating electrical equipment with brushes, it is inevitable that the brush will wear off the carbon tip. At this point, what you need to do is change the brushes for your device. In addition, if you assemble some new equipment without a brush, you will definitely have to buy it. Here we will help you with some essential information to keep in mind before looking to buy carbon brushes to assemble or replace your device.

To choose the right type of brush, you need to provide the following information to the seller or the manufacturer of the brush:

- Know the parameters of the brush you need such as: Brush code, brush size (how thick, how wide, how long), what kind of wire is the diameter, and information about the core.

- Know the parameters of the motor using brushes such as: rotational speed, current used, power of the device or voltage.

Some popular brush products:

- Carbon brush CB-203A: for washing machine (HW1200, HW1300), milling machine (RP1800, RP1801, RP2301FC), cutting machine (LC1230).

- D172 Brushes: Widely used in engines supplied in the size specified by the customer.

- Brush D374N: Widely used in motors, this brush type generator is also available in the size specified by the customer.

Currently, although there is a brushless motor that makes the device have a longer life, higher capacity, and does not cost more for maintenance and replacement of brushes, however, equipment using brushes is still produced. produced and used a lot because the price is much cheaper. So in the future there will still be a lot of devices using brushes as an economic problem.

Contact for detailed advice: 093.659.2556

- Bao An Technical Service Joint Stock Company - Bao An Automation

- Address: Van Tra, An Dong, An Duong, Hai Phong City

- Hotline: 093.659.2556

- Website: https://baoanjsc.com.vn

- Email: baoan@baoanjsc.com.vn

- Fanpage: https://www.facebook.com/BaoAnAutomation

- Bao An Automation - Distributor of SICK electrical equipment in Vietnam

- Economy digital torque meter

- Dong IL ASG-A050W antistatic bar: Effective solution for industrial environment

- Bengine EBS Medium Torque Series Electric Screwdriver

- CSS High Resolution Sensor - SICK's ultra-precise color detection solution