An Energy Management Framework for next-gen factory based on context-awareness

1. Factory in near future

Nowadays, manufacturing is changing considerably in many countries and that is known as a fourth industrial revolution. While the introductions of steam power, the assembly line and early automation drove the first three industrial revolutions, machine intelligence will be the main technology for the fourth one. Advances in electronic intelligence make it possible for equipment to measure and change processes, and for factories to communicate over a wide area.The performance of facilities in factories becomes reduced, and the energy consumption gets higher because of the ageing and malfunction. So, efficient energy management is essential for maintaining initial performance and managing well the facilities. However, facilities of the most of factories are not managed systematically or professionally, since the existing energy management are performed based on the facility managers’ experience and habits. To solve these problems, many kinds of automatic and intelligent energy management technologies are developed and used these days.

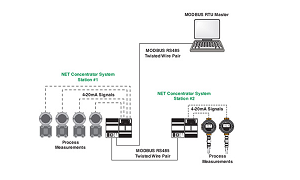

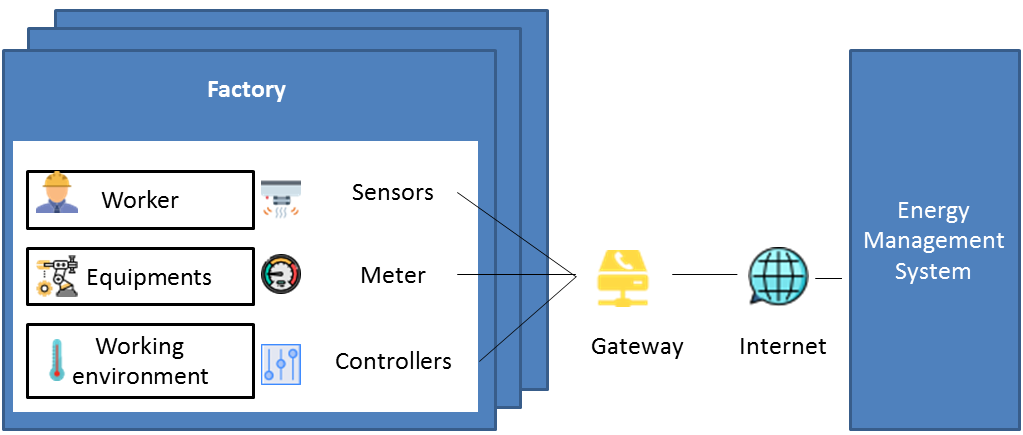

The components of the energy management is shown in Figure 2, including factory, gateway, and EMS. We call the energy management system for factory as EMS, which has similar functions as the existing EMS. In a factory, sensors, meters and controllers are added on to the existing personnel, equipment, and environment in the traditional factory. The data from the sensors and meters are sent to the EMS through the gateway.

Then, the data is transformed to the information and analysed to detect the energy leakage or abnormal state in the factory. In case of the unusual states of operation or the energy consumption, it is notified to the designated users to solve the state. The users check the facilities or equipment and prevent the useless energy consumption.