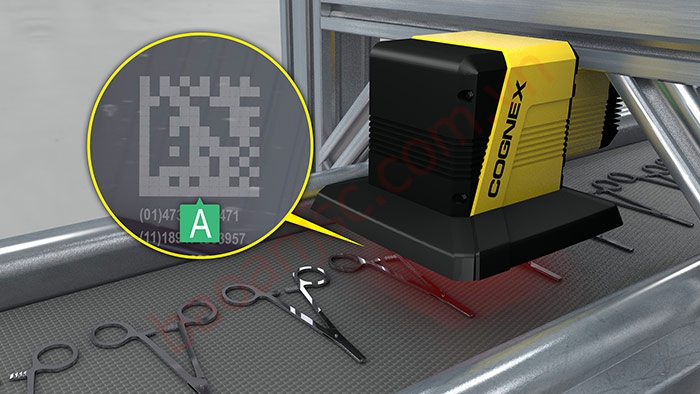

COGNEX: WHAT IS BARCODE VERIFICATION?

From manufacturers to packagers and retailers, companies across industries use barcodes to track products from production to the point of sale. A failure to scan a barcode can be catastrophic, slowing down production lines and causing costly reprints, wasted product, and retailer chargebacks. An increasing number of industries require compliance to the International Organization for Standardization (ISO) code quality guidelines or have their own barcode quality parameters that need to be met and checked. So how can barcode producers ensure their codes are readable? Where can they look for guidance to adjust their marking processes, and how can they certify their codes meet industry requirements?

Barcode verification is the process of grading the quality of 1D, 2D, and direct part mark (DPM) codes to specified standards. Many producers already monitor the quality of their codes using process control metrics (PCM) and data validation software on their barcode readers. Though a step in the right direction, this is not true verification and can leave producers unprotected down the supply chain. Validation looks only at the format of the data within a code and does not check print quality. And while PCM tests the same quality parameters as verification, results are unique to a reader’s particular setup and will only tell you if that reader can read the code, instead of being reader agnostic. Process control metrics by their nature are often tuned to a particular process, and some parameters may be omitted or modified since there is no standard.

Barcode verifiers and software report on code quality parameters and validate data for conformance to ISO/IEC 15415, ISO/IEC 15416, and AIM DPM (ISO/IEC TR 29158) guidelines. Three major verification standards govern 1D, 2D, and DPM codes.

- 1D barcodes use ISO 15416

- 2D barcodes printed on a label use ISO 15415

- 2D DPM barcodes use ISO/IEC TR 29158, also known as AIM DPM

Some industry committees have developed application standards mandating that their manufacturers comply with their rules for barcode marking. An application standard outlines what type of symbology is acceptable, what ISO standard to grade against, the minimum acceptable grade, aperture, x-dimension range, lighting required, and how the data within the barcode must be formatted. Application standard examples includes:

- Unique Device Identification (UDI), an FDA mandate for all medical devices

- GS1, a standard to regulate barcode quality for retail, transportation, and food service industries

- Unique Identifier (UID) for MIL-STD-130, a standard designed to help the US Department of Defense with tracking items

Barcode verifiers require calibration, use specified lighting, and check all quality parameters. Conformance cards are a widely used industry tool designed to support proper calibration of verifiers. Conformance calibration cards contain symbols with intentional imperfections that are used to check the reporting capabilities of the verifier and document conformance to industry standards such as ISO/IEC 15415 and GS1 specifications. Dome lighting, 30-, 45-, and 90-degree lighting options illuminate the target on a range of code surfaces. This provides the best chance of reliably capturing and grading code images to meet ISO standards. An overall grade (usually A through F) is assigned based on several parameters such as symbol contrast, modulation, pattern damage, and decodability. Typically, a barcode with a grade of C or better is considered a passing code.

By monitoring verification results, code issues can be identified when quality starts to decline and take corrective action right away. A verifier also generates reports to certify the quality of a producer’s codes. Reports can be printed or exported to a storage archive to prove compliance with contract and industry requirements.

For more information: 0936.985.256

- BAO AN TECHNIQUE SERVICE JOINT-STOCK COMPANY

- Address: Vân Tra, An Đồng, An Dương, Hải Phòng city

- Hotline: 0936.985.256

- Website: https://baoanjsc.com.vn

- Email: baoan@baoanjsc.com.vn.

- Fanpage: https://www.facebook.com/BaoAnAutomatio

30112018030452.jpg)