Methods to electrostatic errors caused by humans

1. Common faults caused by static electricity

In factories that produce electronic components, phones, screens... encounter a lot of ESD errors that cause damage that greatly affects specific brands. Two common failures are:

Direct product failure : This error occurs immediately after equipment failure, accounting for 40% of factories. This error is easily recognized and can be seen through the PE and QC inspection stages, causing great damage to the factory.

Potential defects in the product : This error is usually difficult to detect immediately or go through the testing stages of the PE department and the QC department does not detect it. When the products are brought out to the market for consumption and use, then the equipment and products are damaged (during the warranty period) or after the warranty period for unknown reasons, leading to the supplier's trademark will be damaged. greatly affected. This error accounts for up to 60% in the factory.

So what is causing the above errors? The main answer is caused by ESD.

So how is ESD caused? : Static electricity is obviously electricity, so it cannot be seen with the naked eye but can only be detected by electric field and voltage meters. And static electricity generated in the factory is mainly due to the following reasons:

- Cause 1: Static electricity due to self-accumulation and self-discharge when exposed to other objects or people.

- Cause 2: Static electricity released by humans into the product.

- Cause 3: Static electricity caused by induction from insulating material placed at the wrong distance.

Of the three reasons above, it is necessary to control static electricity in the factory, especially for humans. Factory personnel need to be trained in and control static electricity when working and handling ESDS electronic components.

Static electricity affects people

2. Human influence on electrostatic control program

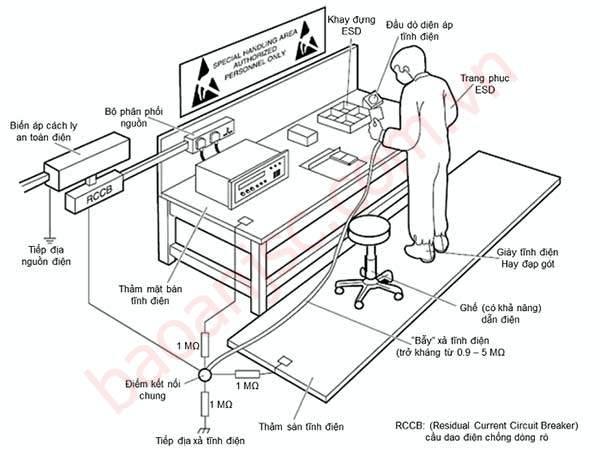

In plant electrostatic control programs, the electrostatics document always addresses the issue of training employees when working in the plant or working in the EPA area. machine). It is always emphasized that all personnel working and manipulating ESDS electronic components must be trained and wear protective equipment and grounded with shoes and floor or via a bracelet.

Static control

Why is it like that? Human is an object that generates static electricity during the process of working and moving. The static electricity generated on the human body and stored in the body until it encounters objects that can discharge static electricity, then the static electricity is discharged. The discharge into the component due to direct contact will destroy the basic connections of the component, causing permanent damage or partial destruction of the component, making the component weaker for a while before it fails. So controlling static electricity on people is extremely necessary for production

3. The most popular methods to limit static electricity on people

People are the cause and source of static electricity generation and directly affect the product, so people need to be discharged from static electricity. In the electrostatic control program, the human grounding method is an important method, it consists of 2 grounding methods

· Ground for people through shoe-floor system

・Earth the person through the bracelet

Anti-static shoes

The above 2 methods are two common methods and are applied in factories where employees wear bracelets. Therefore, we need to choose the right method to apply in the factory with the highest efficiency.

In addition, using ionzer devices such as: anti-static bars, anti-static fans, anti-static guns... will minimize the possibility of electrification to people and products. Bao An is currently an authorized distributor of Dong-IL (Korea) antistatic equipment in Vietnam.

To be able to choose the right anti-static equipment product as well as ensure genuine products, please contact us via baoan@baoanjsc.com.vn . With the motto of professional and dedicated work, Bao An Automation is always committed to providing customers with the best quality products at reasonable prices and ensuring on-time delivery.

Bao An authorized distributor of antistatic equipment Dong-IL (Korea)

Contact for detailed advice: 093.659.2556

- Bao An Technical Service Joint Stock Company - Bao An Automation

- Address: Van Tra, An Dong, An Duong, Hai Phong City

- Hotline: 093.659.2556

- Website: https://baoanjsc.com.vn

- Email: baoan@baoanjsc.com.vn

- Fanpage: https://www.facebook.com/BaoAnAutomation

Articles to see:

- Dong IL ASG-P series Static Eliminator

- Dong IL MF-A902A khử Deionizing Fan

- Dong IL ARS-M002ZA electrostatic alarm device

- Anti-static gun - ION GUN DONG IL ZM-G1G Series

- Ion Blower DONG IL AMF-95 Series