Schneider Inverter ATV310 series

Series: Schneider Inverter ATV310 series

Features

- Schneider Inverter ATV310 has small size, that should be suitable with the application of the terminal device in the industry.

- Protect motor.

- Work in hard working

- Smooth Operation.

- Tackling Power Loss and Recovery.

- Inverter ATV310, Energy Saving, Environmental Features, Safety.

Specifications

|

Application of Schneider Inverter ATV310 |

ND: Fans, Pumps, HD: conveyor, packing machine, printer, material handling… |

|

Power supply |

3P, 360V to 480Vac (− 15% to +10%) 50/60 Hz (± 5%) |

|

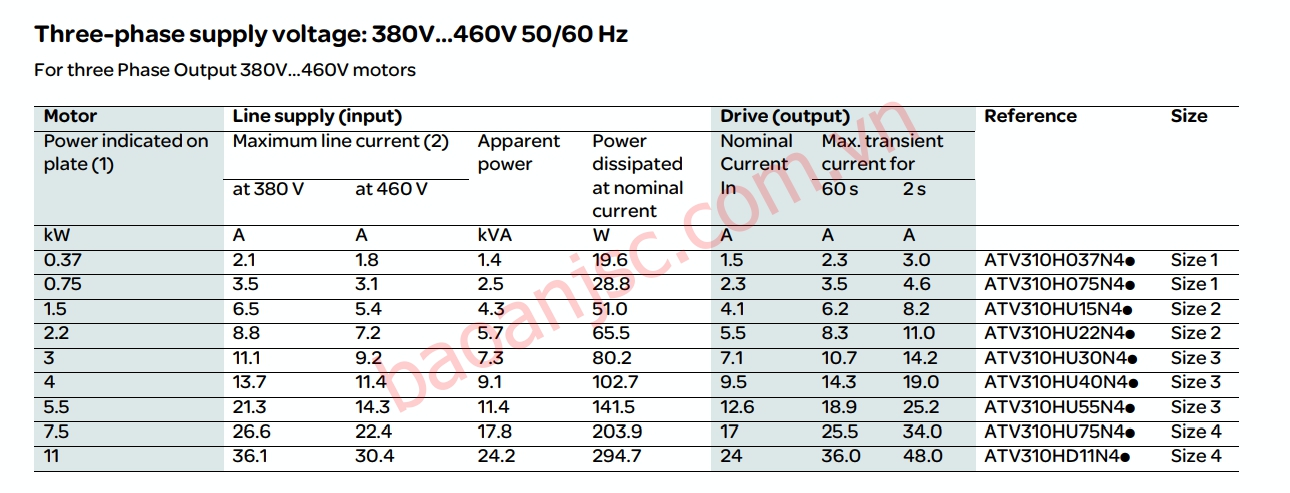

Rated capacity |

0.37-11kW |

|

Rated current |

2.5- 40A |

|

Output frequency range |

-400 to 400 Hz |

|

Starting Torque |

170...200 % of nominal motor torque depending on drive rating and type of motor |

|

Overload current rating |

Internal supply for reference potentiometer : 5 V (4.75...5.25 V) DC 10 mA with overload and shortcircuit protection Internal supply for logic inputs : 24 V (20.4...28.8 V) DC 100 mA with overload and short-circuit protection |

|

Control Method |

Asynchronous motor control, V/F control, Sensorless vector control. |

|

Braking unit |

Up to 150 % of nominal motor torque with braking resistor at high inertia Up to 70 % of nominal motor torque without braking resistor |

|

Input |

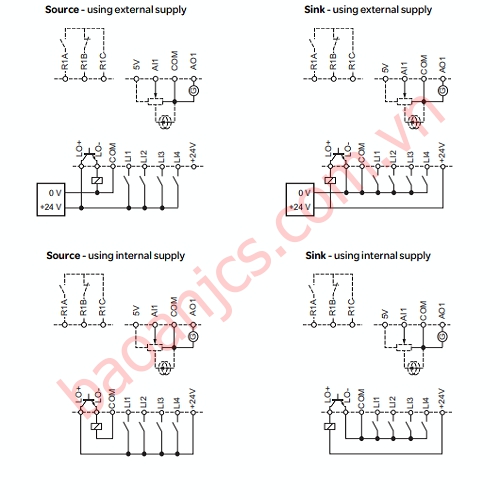

Analogue input type Configurable current (AI1) 0...20 mA, impedance 250 Ohm Configurable voltage (AI1) 0...10 V, impedance 30 kOhm Configurable voltage (AI1) 0...5 V, impedance 30 kOhm Discrete input type 24 V (18...30 V) programmable, at LI1...LI4 terminal(s) Discrete input logic Positive logic (source), 0...< 5 V (state 0), > 11 V (state 1) Negative logic (sink), > 16 V (state 0), < 10 V (state 1), input impedance 3.5 kOhm |

|

Ouput |

Analog Output, AO1 software-configurable voltage : 0...10 V, impedance: 470 Ohm, resolution 8 bits AO1 software-configurable current : 0...20 mA, impedance: 800 Ohm, resolution 8 bits Discrete output (LO+, LO-) logic output (R1A, R1B, R1C) protected relay output 1 C/O |

|

Protection Function |

Against input phase loss in three-phase Thermal motor protection via the drive by continuous calculation of I²t Line supply overvoltage Line supply undervoltage Overcurrent between output phases and earth Overheating protection Short-circuit between motor phases |

|

Main Control Functions |

2-wire type control, Auto-tuning, PID(wake up function), Torque Control, Underload Time Delay, Overload Time Delay, Speed/Torque Control, 3-wire control. |

|

Communication |

Modbus RJ45 for Modbus on front face, Physical interface: 2-wire RS 485 for Modbus Transmission frame: RTU for Modbus |

|

Peripheral Devices and Options |

HMI, Card |

|

Degree of protection |

IP41 on top IP20 without blanking plate on upper part |

Ordering information

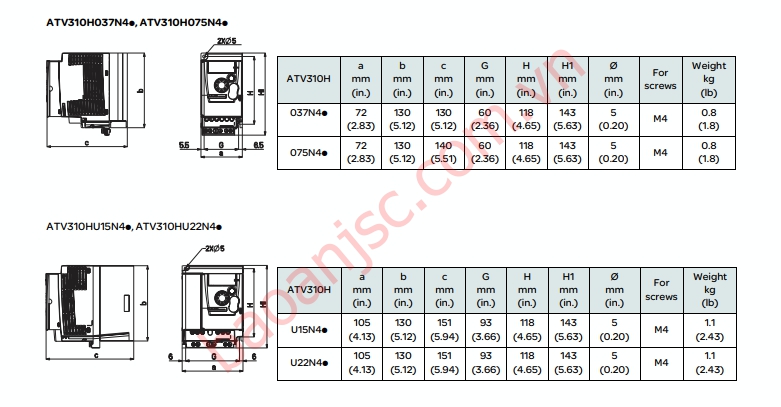

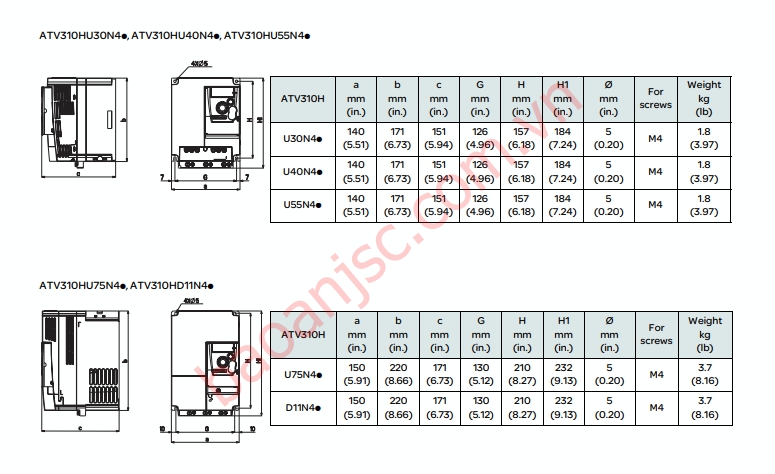

Dimensions

Connections