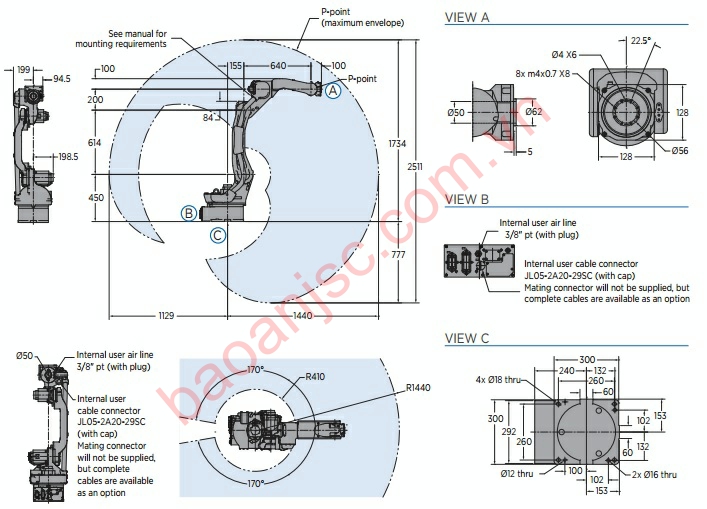

Yaskawa Arc Welding Robot MA1440 series

Series: Yaskawa Arc Welding Robot MA1440 series

Features

- Slim, fast six-axis MA1440 welding robot increases productivity and achieves highest welding performance.

- Large, 50 mm thru-hole for torch cabling, sensor wires and water cooling. Eliminates cable interference, simplifies programming and reduces cable wear.

- 6 kg payload supports motorized torches and sensors.

- Hollow upper arm maintains optimum bend radius of welding torch cable, maximizing weld performance. T-axis can rotate torch ±210 degrees without cable interference.

- New, contoured arm design reduces interference with jigs and large parts.

- Optimized mounting area for feeder reduces interference.

- Minimal U-axis cable protrusion eliminates peripheral equipment interference.

- Symmetric wrist profile provides equal torch access to both sides of part.

- Ideally suited for use in high-density work cells with multiple robots working in close proximity.

- Slim arm allows easy access to parts in tight spots and avoids potential interference with fixtures.

- Floor-mounted model is standard. Wall- or ceiling-mounted versions are available.

Specifications

|

Application |

Arc welding |

|

Controller |

DX200 |

|

Controlled Axis |

6 |

|

Payload |

6kg |

|

Vertical reach |

2511mm |

|

Horizontal reach |

1440mm |

|

Repeatability |

±0.08mm |

|

Mounting

|

Floor, wall, ceiling |

|

Range of motion |

S-axis ( turning) :-170° - +170° |

|

L-axis (lower arm) : -90° - +155° |

|

|

U-axis (upper arm): -175° - +240° |

|

|

R-axis (arm roll): -150° - +150° |

|

|

B-axis (wrist bend): -135° - +90° |

|

|

T-axis (tool flange): -210° - +210° |

|

|

Maxium speed |

S-axis (swivel base) : 230°/s |

|

L-axis (lower arm) : 200°/s |

|

|

U-axis (upper arm): 230°/s |

|

|

R-axis (arm rol): 430°/s |

|

|

B-axis (wrist bend): 430°/s |

|

|

T-axis (tool flange): 630°/s |

|

|

Mass |

130kg |

|

Power requirements |

1.5kVA |