Yaskawa Inverter Z1000 series

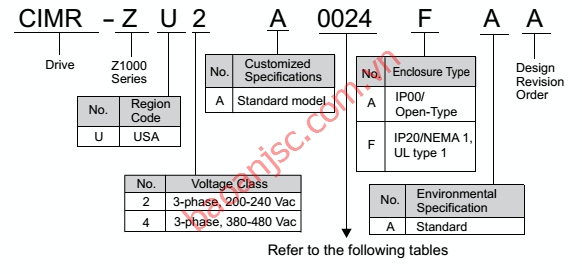

Series: Yaskawa Inverter Z1000 series

Features

- Yaskawa Inverter Z1000 has the Most Advanced Drive Technology.

- The Z1000 features HVAC application-specific software macros, a Hand-Off-Auto LCD keypad, and a real time clock for system

- Built-in 5% line impedance for input harmonic reduction. Noise Filter on board EMI/RFI filter complies with IEC 61800-3 restricted distribution for first environment

- Embedded BACnet communications (BTL Certified), along with Modbus/Memobus, Metasys and Apogee FLN help Z1000 inverter can be easily integrated with control systems, building automation, such as Johnson Controls, Honeywell ... and other control devices with the corresponding protocol.

- Besides the ability to connect to the inverter Z1000 Scada system is full of special features to be able to control the application pumps, fans, HVAC independently. Real-time clock to record the date and time of the event, along with the timer control speed change starting and stopping without external control devices.

- Maintains a set point for closed loop control of fans and pumps for pressure, flow or temperature regulation and eliminates the need for a closed loop output signal from a BAS. Independent PI to control an external device in the system.

- Choose from pre-configured set up macros to match the application for quick and easy set up.

- Inverter Z1000, Energy Saving, Environmental Features, Safety.

Specifications

|

Application of Inverter Yaskawa Z1000 |

Fans, pumps, cooling towers, HVAC |

|

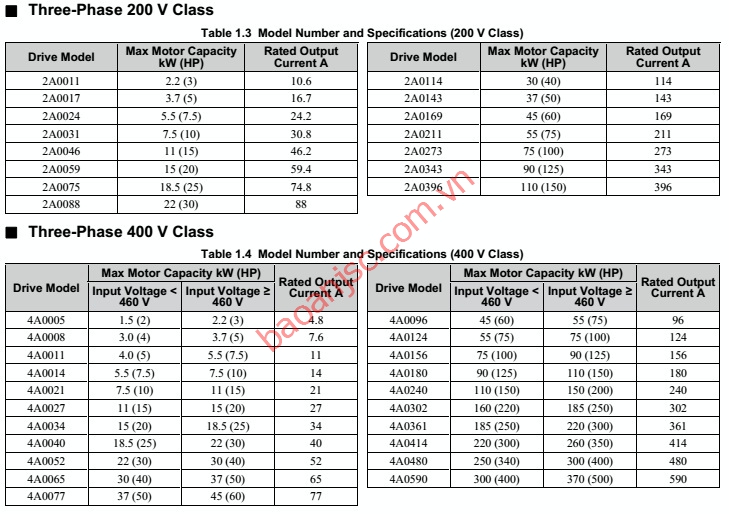

Power supply |

3 pha 200V-240V, 3 pha 380-480V (− 15% /+10% ) 50-60Hz (± 5%) |

|

Rated capacity |

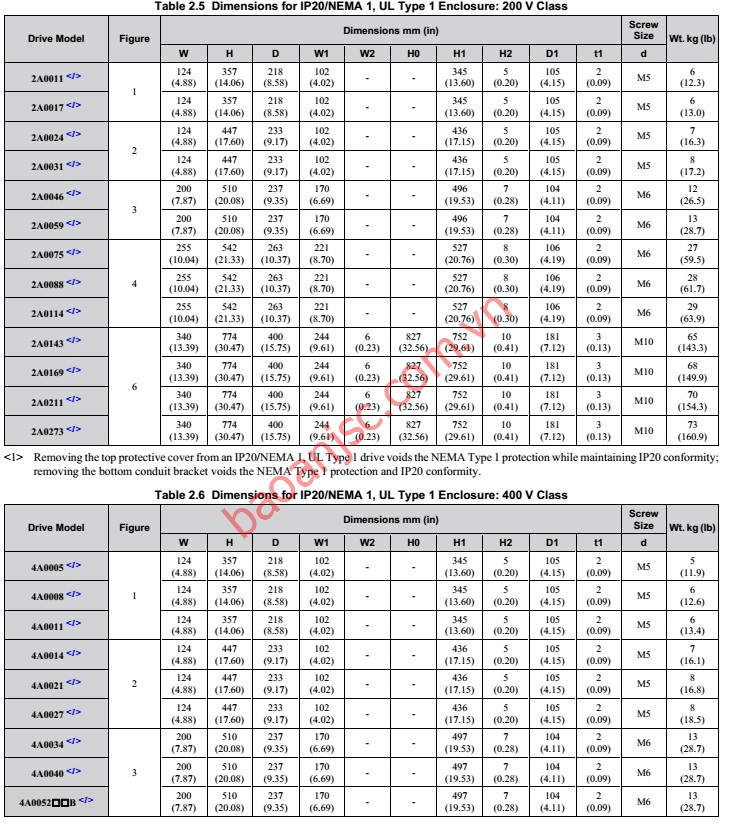

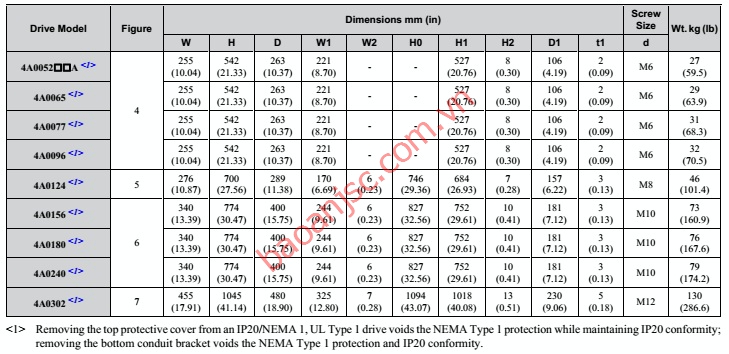

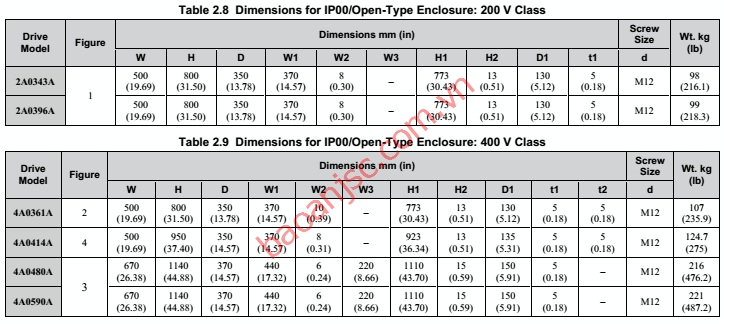

2.2-110kw (200-240V), 1.5-300kw (380-480V) |

|

Rated current |

10.6-396A (200-240V), 4.8-590A (380-480V) |

|

Output frequency range |

0.01-240Hz |

|

Starting Torque |

V/f: 140% at 3 Hz OLV/PM: 50% at 6 Hz |

|

Overload current rating |

110% of rated output current for 60 s |

|

Control Method |

V/Hz Control, Open Loop Vector Control for Permanent Magnet motors |

|

Braking unit |

- |

|

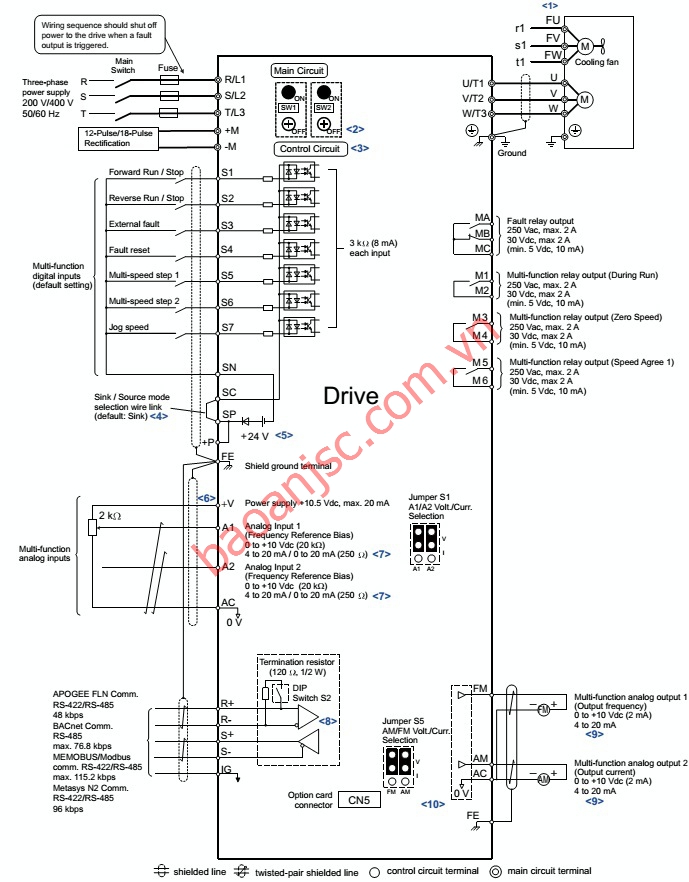

Input |

Multi-Function Programmable Digital Inputs (24Vdc), Multi-Function Programmable Analog Inputs (0-10VDC or 4-20mA) |

|

Ouput |

Fault Relay Output (Form C - 2 Amps at 250Vac max), Multi-Function Programmable Relay Output (Form A - 2 Amps @ 250Vac max), Multi-Function Programmable Analog Outputs (0-10Vdc or 4-20mA), 4 Vdc, 150 mA Transducer or Transmitter Power Supply for customer use |

|

Protection Function |

Motor Protection, Momentary Overcurrent Protection, Overload Protection, Overvoltage Protection, Undervoltage Protection, Momentary Power Loss Ride -Thru, Heatsink Overheat Protection, Braking Resistance Overheat Protection, Stall Prevention, Ground Fault Protection: Protection by electronic circuit, DC Bus Charge LED |

|

Main Control Functions |

Momentary Power Loss Ride-Thru, Speed Search, Overtorque/Undertorque Detection, 4 Step Speed |

|

Communication |

RS-422 /485 Programmable up to 76.8 kbps. BACnet, LONWORKS, EtherNet/IP, Modbus TCP/IP, Metasys / APOGEE FLN |

|

Peripheral Devices and Options |

Network Communications, Support Tools, Digital Operator and Software, External Heatsink Kits NEMA 12, External Heatsink Kits for 200V-400V-600V, 24 Vdc Control Power Unit, End Cap Kits NEMA 1 |

|

Degree of protection |

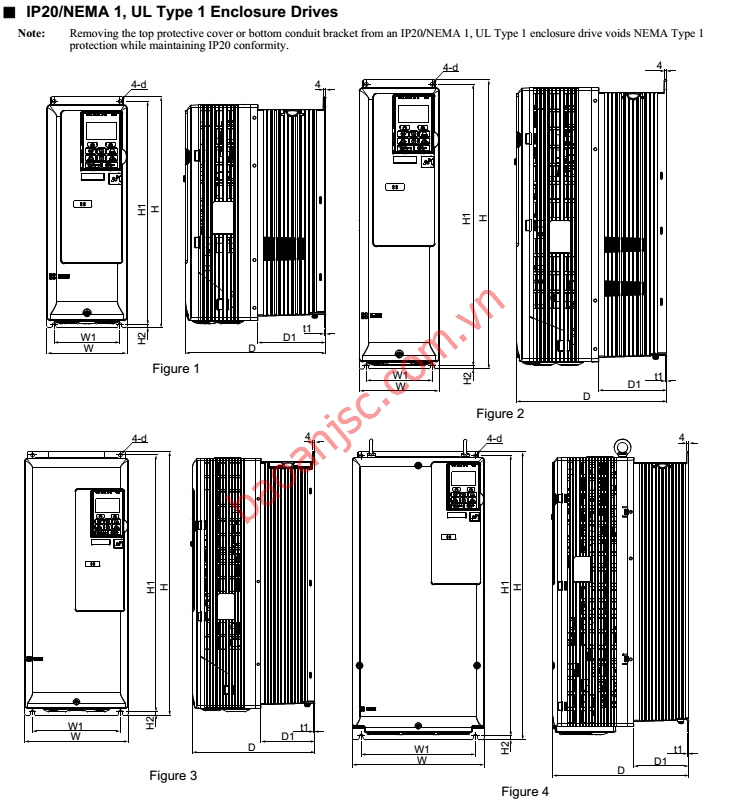

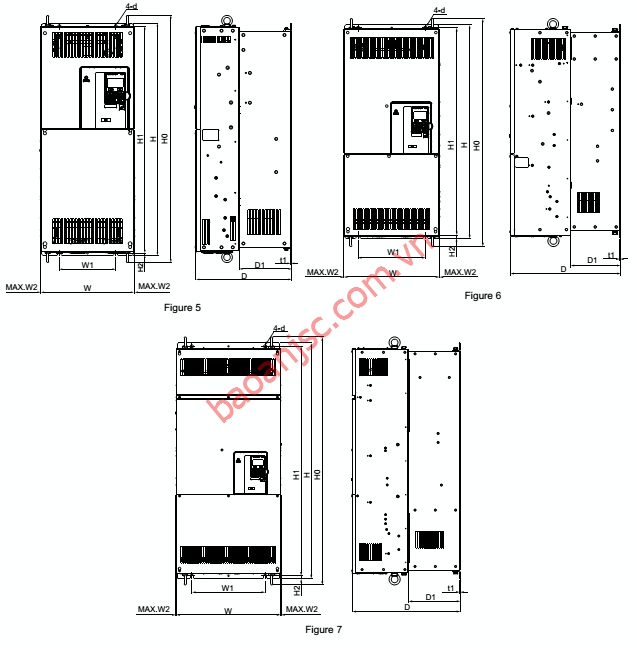

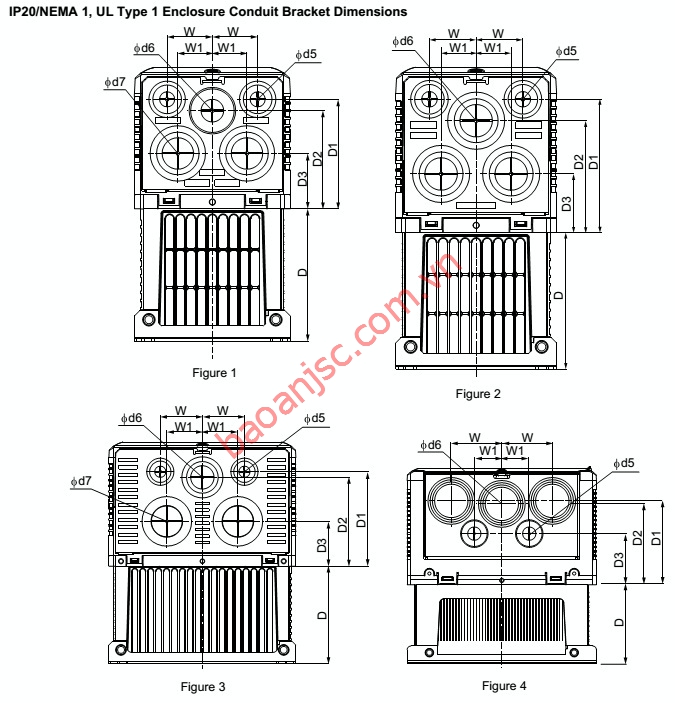

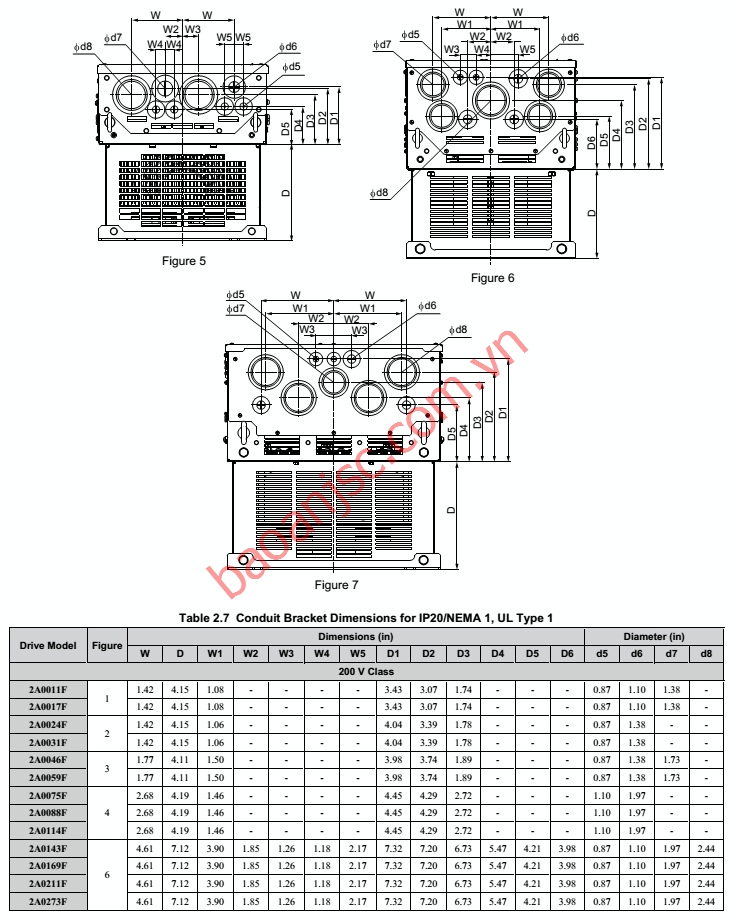

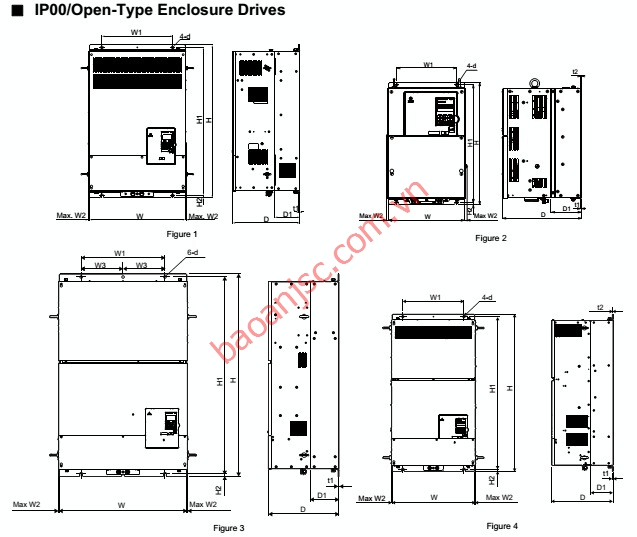

IP00/Open Type enclosure, IP20 NEMA 1, UL Type 1 enclosure |

Connections