Yaskawa Robot spot welding MS165 series

Series: Yaskawa Robot spot welding MS165 series

Features

- The 6-axis robots have an advantage over conventional heavy duty robots thanks to their streamlined design and ability to use smaller spot welding guns, and the ability to position the robots closer to the workpiece shortens the welding lines, reduces the cycle times and as a result provides for flexible adjustment of the welding lines. The internally routed cables extend from the L-axis to the robot socket and through the centre of the S-axis.

- Speeds 43% faster than large payload robot for reduced cycle and takt times

- Compact and ideal for use in flexible, high-density layouts

- Offers 50% combined power savings used with lighter, more efficient DC gun

- Guns are available in X- or C-type configurations with 600-kg clamping force and 15,000-Amp capacity.

- Proven integrated spot harness, prevents interference and reduces programming time. Integrated cabling and hoses last more than six times longer than traditional harnesses, reducing maintenance and improving uptime.

Specifications

|

Application |

Spot welding |

|

Controller |

DX200 |

|

Controlled Axis |

6 |

|

Payload |

165kg |

|

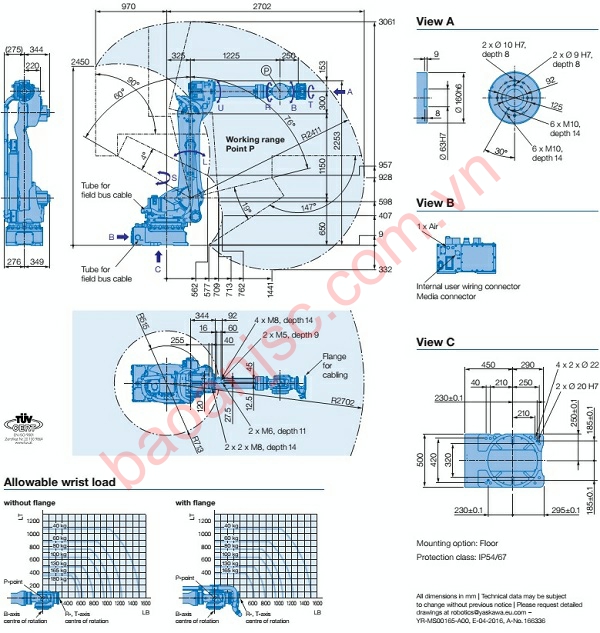

Vertical reach |

3393mm |

|

Horizontal reach |

2702mm |

|

Repeatability |

±0.02mm |

|

Mounting |

Floor |

|

Range of motion |

S-axis ( turning) :-180° - +180° |

|

L-axis (lower arm) : -60° - +76° |

|

|

U-axis (upper arm): -147° - +90° |

|

|

R-axis (arm roll): -360° - +360° |

|

|

B-axis (wrist bend): -130° - +130° |

|

|

T-axis (tool flange): -360° - +360° |

|

|

Maxium speed |

S-axis (swivel Base) :125°/s |

|

L-axis (lower arm) : 115°/s |

|

|

U-axis (upper arm): 125°/s |

|

|

R-axis (arm Rol): 182°/s |

|

|

B-axis (wrist Bend): 175°/s |

|

|

T-axis (tool flange): 265°/s |

|

|

Mass |

970kg |

|

Power requirements |

5.0kVA |